1999-2003 FORD SUPER DUTY F SERIES HIGH PRESSURE OIL PUMP LEAK - FORD: 1998-2003 E SERIES 1999-2003 SUPER DUTY F SERIES 2000-2003 EXCURSION, F-650, F-750 This article supersedes TSB 03-21-50 to update the WARNING service procedure

and illustration. DO NOT REMOVE OR ATTEMPT TO REPAIR A LEAK AT THE PLUG

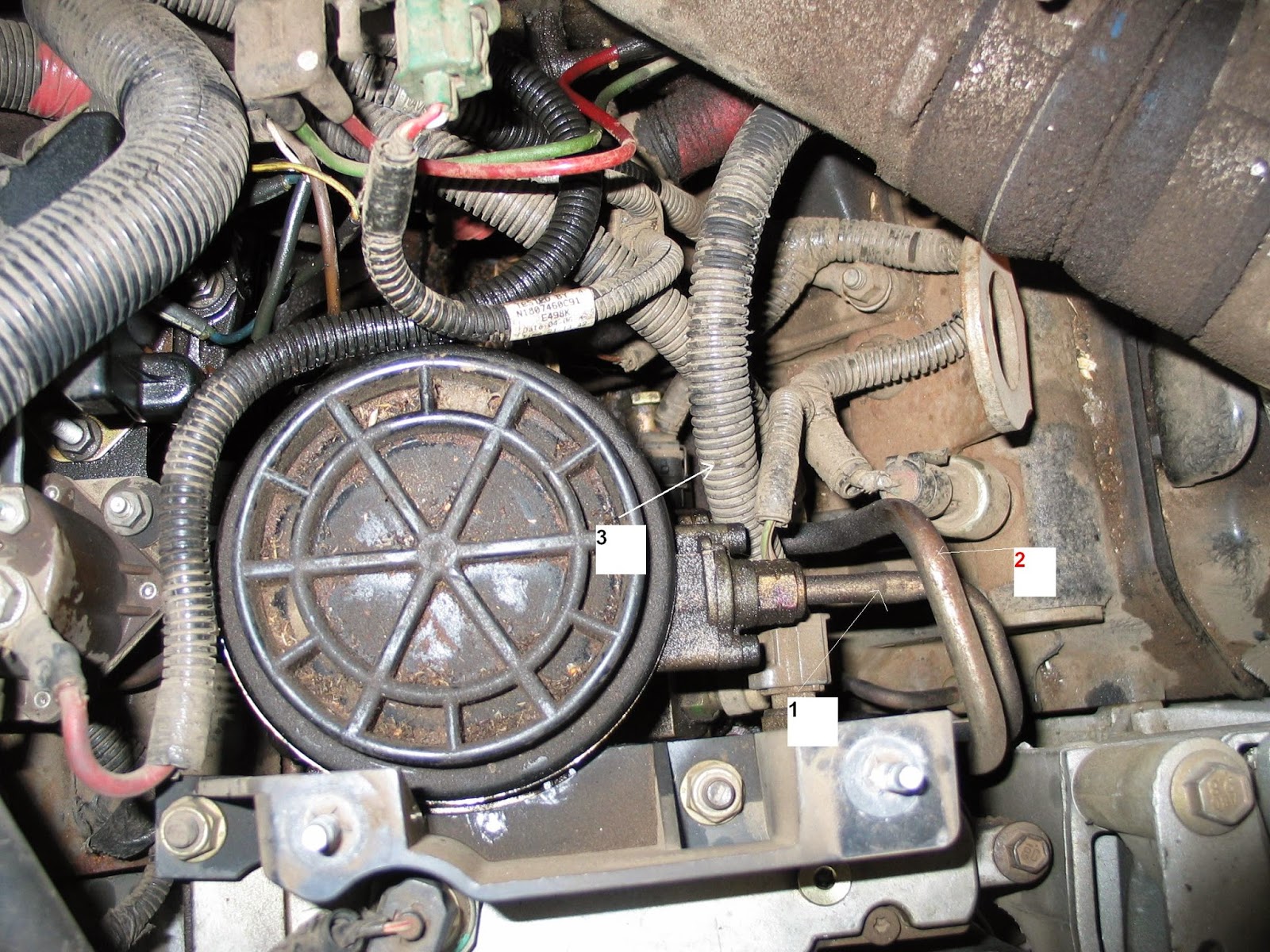

PICTURED IN LOWER LEFT ISSUE CORNER OF FIGURE 1, OR DAMAGE TO THE Some

1998-2003 E-Series, 1999-2003 Super Duty, PUMP WILL RESULT. 2000-2003

Excursion, and 2000-2003 F650/750 1998-2003 E-SERIES HIGH PRESSURE OIL vehicles equipped with a 7.3L Diesel engine may PUMP ACCESS PROCEDURE (DISASSEMBLY) exhibit an oil leak at the high pressure oil pump outlet fittings and/or end plug (see Figure 1).

The 1. Remove the Intake Air Resonator. For leak may appear to be a rear main crankshaft seal, additional information, refer to Section 303-12 in oil pan gasket, or other engine oil leak due to the the appropriate Workshop Manual. drain hole machined in the crankcase valley which allows any oil in the valley to run down the back of 2. Remove the exhaust back pressure sensor. the engine. a.

Disconnect the exhaust back pressure ACTION sensor electrical connector. High pressure oil pump leaks at the outlet fittings b. Remove the exhaust back pressure sensor. and/or end plug can be serviced without removing the pump assembly. Replace the O-rings on the 3. Remove the high pressure oil pump reservoir. fittings and the end plug using Kit 2C3Z-9G804-AA. For additional information, refer to Section All three (3) O-rings should be replaced. Apply 303-04 in the appropriate Workshop Manual. liquid thread sealer (included in the kit) prior to WARNING reinstallation.

Refer to the following Service Procedure for details. 4. Open the fuel/water separator drain valve to FOLLOW THE PROPER HIGH PRESSURE OIL release fuel pressure. Completely drain the fuel PUMP ACCESS PROCEDURE IN THIS filter/water separator assembly. DOCUMENT FOR ACCESS TO THE HIGH 5. Disconnect the fuel supply and fuel return lines PRESSURE OIL PUMP. from the fuel filter/water separator. NOTE 6. Disconnect the two (2) cylinder head fuel FOR SUPER DUTY AND EXCURSION, PROCEED supply lines from the fuel filter/water separator. TO O-RING SEAL REPLACEMENT PROCEDURE.

Download : 1999-2003 FORD SUPER DUTY F SERIES HIGH PRESSURE OIL PUMP LEAK

The 1. Remove the Intake Air Resonator. For leak may appear to be a rear main crankshaft seal, additional information, refer to Section 303-12 in oil pan gasket, or other engine oil leak due to the the appropriate Workshop Manual. drain hole machined in the crankcase valley which allows any oil in the valley to run down the back of 2. Remove the exhaust back pressure sensor. the engine. a.

Disconnect the exhaust back pressure ACTION sensor electrical connector. High pressure oil pump leaks at the outlet fittings b. Remove the exhaust back pressure sensor. and/or end plug can be serviced without removing the pump assembly. Replace the O-rings on the 3. Remove the high pressure oil pump reservoir. fittings and the end plug using Kit 2C3Z-9G804-AA. For additional information, refer to Section All three (3) O-rings should be replaced. Apply 303-04 in the appropriate Workshop Manual. liquid thread sealer (included in the kit) prior to WARNING reinstallation.

Refer to the following Service Procedure for details. 4. Open the fuel/water separator drain valve to FOLLOW THE PROPER HIGH PRESSURE OIL release fuel pressure. Completely drain the fuel PUMP ACCESS PROCEDURE IN THIS filter/water separator assembly. DOCUMENT FOR ACCESS TO THE HIGH 5. Disconnect the fuel supply and fuel return lines PRESSURE OIL PUMP. from the fuel filter/water separator. NOTE 6. Disconnect the two (2) cylinder head fuel FOR SUPER DUTY AND EXCURSION, PROCEED supply lines from the fuel filter/water separator. TO O-RING SEAL REPLACEMENT PROCEDURE.

Download : 1999-2003 FORD SUPER DUTY F SERIES HIGH PRESSURE OIL PUMP LEAK

05.25

05.25

Unknown

Unknown