Ford C-4 Bracket and Lever Installation Instructions - STEP 1. Raise and safely support the vehicle at least 1-2 feet off the ground. Remove the nut and lock- washer holding the downshift linkage onto the downshift lever shaft.

The downshift lever is the outer lever on C-4 transmissions. Pull the

lever off the shaft and allow the linkage to hang free. Remove and

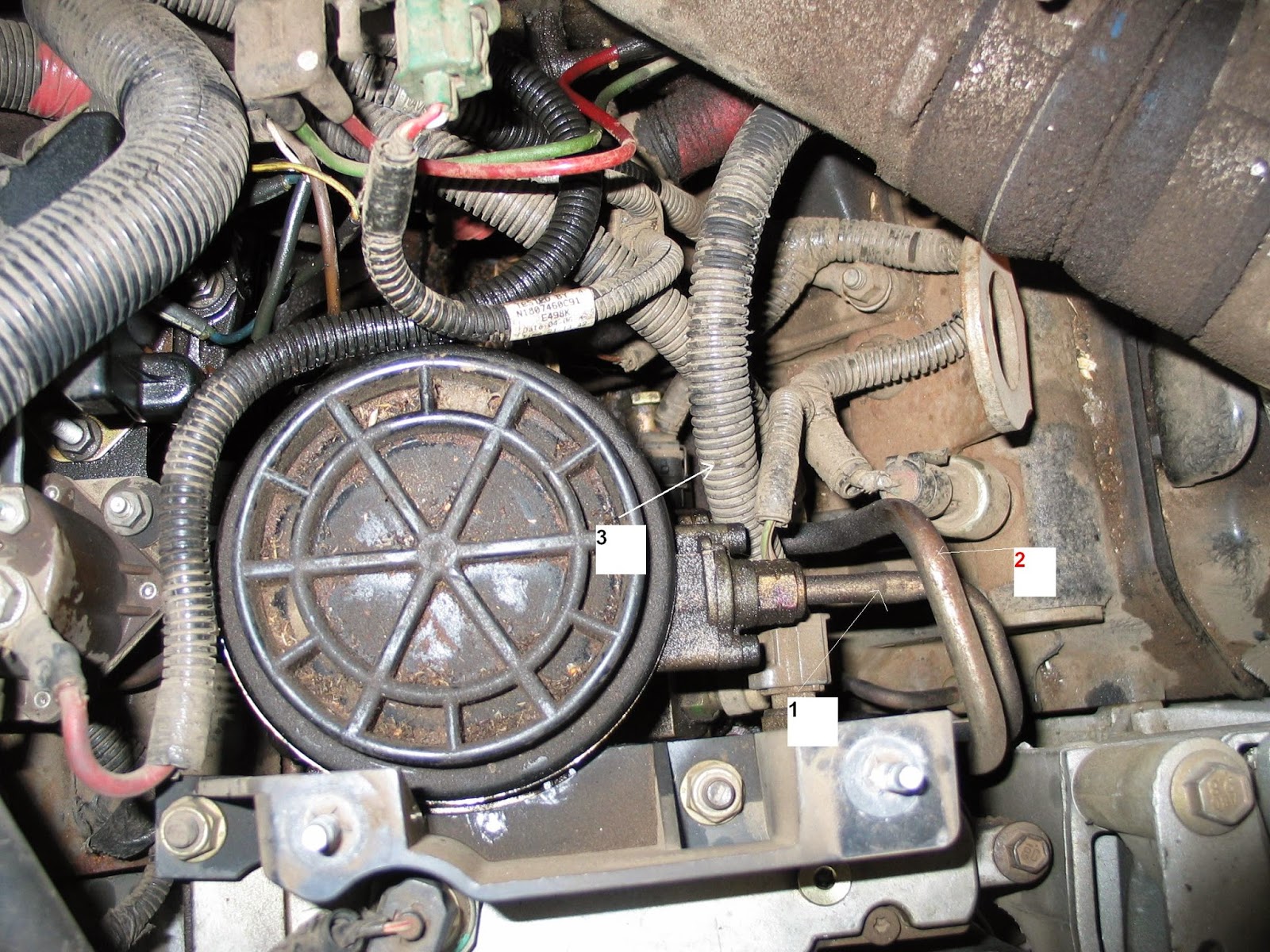

discard stock shift linkage rods. Late C-4 transmissions have a Neutral safety/Backup light switch on the transmission shift lever. If your transmission is so equipped, remove the two bolts holding the switch in place and slide it off the shift shaft. Disconnect the switch at the factory plug and discard it. STEP 2. Install the B&M

selector lever, See figure 1 . Note: The B&M lever must point

downward for proper operation. If the stock shift lever on your transmission points

down, you will have to remove the lower part of the stock arm by

cutting it off to clear the B&M lever, (See figure 1 ) . Install

B&M selector lever onto shift shaft of transmission. Align selector

lever so when it points straight down it travels equal arcs in both

directions from center, then tighten 1/4″-20 x 1 1/2″ pinch bolt

and nut. The lever should travel smoothly from front to back with a

positive click in each gear position. Make sure O-ring is in position on

downshift shaft and install downshift. lever in position on shaft.

Install lockwasher and nut and tighten securely. Downshift lever must operate smoothly.

Reconnect downshift linkage. STEP 3. Remove the two lower bolts from the rear servo cover. Install cable bracket in position, (See figure 1 ). Install two servo cover bolts as removed and tighten 12-13 ft. lbs. Do not overtighten as this can distort servo cover. STEP 4. Route the shifter cable according to figure 2 Avoid kinks and sharp bends and route the cable away from hot engine or exhaust parts. Remove the two rubber boots, one large nut, and a large lock- washer from the threaded end of the shifter cable. Slide the end of the cable into the cable bracket, Install large nut and lockwasher loosely over end of cable. Install two rubber boots onto end of cable. Install the swivel on the threaded end of the cable and position it in the center of the threaded portion. STEP 5. Move the transmission selector lever by hand to full rear position (LOW). Place the shifter lever to the low gear position (ratcheted all the way back). Adjust the large nuts on the cable so that the swivel will slide into the hole on the selector lever. Tighten the large nuts completely. Be sure that the swivel will slide freely in and out of the hole in the selector lever.

Download : Ford C-4 Bracket and Lever Installation Instructions

Reconnect downshift linkage. STEP 3. Remove the two lower bolts from the rear servo cover. Install cable bracket in position, (See figure 1 ). Install two servo cover bolts as removed and tighten 12-13 ft. lbs. Do not overtighten as this can distort servo cover. STEP 4. Route the shifter cable according to figure 2 Avoid kinks and sharp bends and route the cable away from hot engine or exhaust parts. Remove the two rubber boots, one large nut, and a large lock- washer from the threaded end of the shifter cable. Slide the end of the cable into the cable bracket, Install large nut and lockwasher loosely over end of cable. Install two rubber boots onto end of cable. Install the swivel on the threaded end of the cable and position it in the center of the threaded portion. STEP 5. Move the transmission selector lever by hand to full rear position (LOW). Place the shifter lever to the low gear position (ratcheted all the way back). Adjust the large nuts on the cable so that the swivel will slide into the hole on the selector lever. Tighten the large nuts completely. Be sure that the swivel will slide freely in and out of the hole in the selector lever.

Download : Ford C-4 Bracket and Lever Installation Instructions

23.32

23.32

Unknown

Unknown

%2BSENSOR.jpg)